Wear Parts: Hydraulic Hammer Maintenance

The life and effectiveness of a hydraulic hammer can be maximized through proper set up and regular maintenance. Proper set up on an appropriately sized host machine is the first step in getting peak performance and the maximum durability. Having the correct hydraulic input will ensure that the internal components are not being stressed prematurely and matching the hammer to the carrier size protects against external forces that can cause structural damage. Regular maintenance and wear component inspection enables components to be replaced before failure. Replacing worn items as needed allows downtime to be scheduled and avoids costly unexpected breakdowns in the middle of a job.

Knowing what to inspect and how to inspect it is sometimes difficult and for that reason we have put together the following guidelines for wear items on our AB series of hydraulic hammers.

The following items are considered wear items: Breaker tool, Lower bushing and Upper bushing, Tool retaining pins, Hydraulic seals, and Suspension components. When damaged or worn, it is the users responsibility to exchange these items to avoid costly damage and downtime and it is highly recommended to stock these parts.

Wear Parts: Limits

Breaker Tool Wear Limits

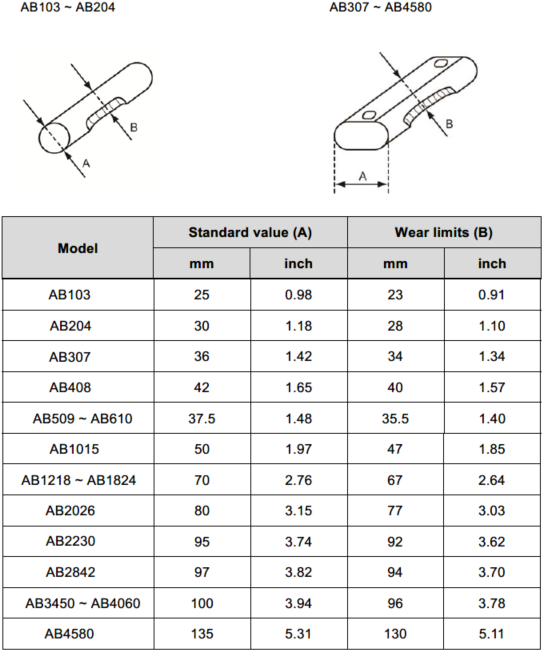

2. Bushing Wear Limits

3. Tool Retaining Pin Wear Limits

4. Hydraulic Seal Wear Limits

Replace the hydraulic seals every 500~600 hours of actual operation as well as units kept over 6 months in storage or at signs of leakage.

AB103 ~ AB1218 : every 600 hours or 6 months

AB1824 ~ AB4580 : every 500 hours or 6 months

5.Suspension Component Wear Limits

Suspension Components : Upper Damper

Suspension Components : Bottom Damper

Suspension Components : Shell Pads